Our Philosophy:

In our work, we focus on developing accessible, high-performance tools and platforms that democratize biofabrication and enhance biomedical research.

An open-source philosophy in bioengineering and research advancement emphasizes transparency, collaboration, and accessibility. It promotes freely sharing data, designs, tools, and findings, allowing researchers worldwide to build on each other’s work. This approach accelerates innovation, reduces duplication, lowers barriers to entry, and fosters a more inclusive scientific community. In bioengineering and 3D bioprinting, open-source models lead to faster development of technologies like FRESH bioprinting, 3D printer design, multi-material capabilities, and universal access to research capabilities by lowering the cost of equipment acquisition, ultimately advancing both science and public health.

Mission: We hope that this site can help to aggregate our open-source projects to allow efficient adoption and improvement of our technology.

3D Bioprinting Open-source Hardware

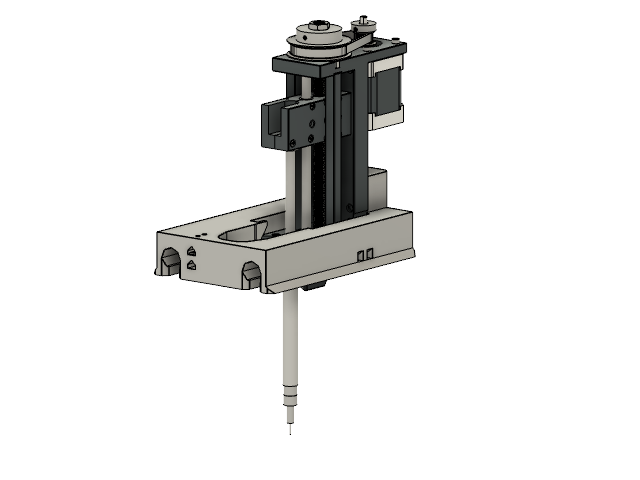

The Replistruder 5 is the newest and highest performance iteration of extrusion-based syringe pumps we have developed for FRESH 3D bioprinting. It achieves nanoliter control of material deposition at an affordable cost. It was an essential technical advance that enabled the creation of Collagen-based High-resolution Internally Perfusable Scaffolds (CHIPS) published in Science Advances in 2025.

The Replistruder 4 takes advantage of the geometry customizability and ease of 3D plastic printing while improving performance by integrating mass produced high-precision linear motion components. Simultaneously this new syringe pump remains compact and lightweight enough for several to be utilized on a 3D bioprinter for multimaterial bioprinting. To facilitate multiple use cases the Replistruder 4 is compatible with a range of syringes including disposable BD and Hamilton gastight syringes. Has been used on a variety of 3D printers (MakerGear, Flashfordge, LulzBot, Ender, etc). Published in HardwareX.

The MakerGear M2 Dual Rep4 3D bioprinter is a desktop plastic printer conversion performed by removing the control board of the printer and replacing it with a Duet 2 WiFi board with a PanelDue 5i touch screen controller (Duet3D, UK). The Duet WiFi board utilizes a preinstalled RepRapFirmware and is compatible with all open-source 3D printing software. This board, in conjunction with the Replistruder 4 syringe pumps, allows for automated two material printing. The printer is easily transported and can fit into a biosafety cabinet for sterile bioprinting.

Extruder Carriage and Replistruder 4 mount for FlashFordge FInder. Here we convert a low-cost 3D printer, the FlashForge Finder, into a bioprinter using our Replistruder 4 syringe pump and the Duet3D Duet 2 WiFi for total cost of less than $900. We demonstrate that the accuracy of the bioprinter’s travel is better than 35 µm in all three axes and quantify fidelity by printing square lattice collagen scaffolds with average errors less than 2%. All components we have designed for the bioprinter conversion are provided as open-source 3D models, along with instructions for further modifying the bioprinter for additional use cases, resulting in a comprehensive guide for the bioprinting field.

The Replistruder 4 High Viscosity, was created to expand the volume and capabilities of the original Replistruder 4. This design has increased rigidity and incorporates 2 lead screws with a carriage that straddles the syringe plunger to eliminate the cantilever geometry. In conjunction with a larger stepper motor, these changes allow for printing higher viscosity soft materials with smaller diameter needle tips.

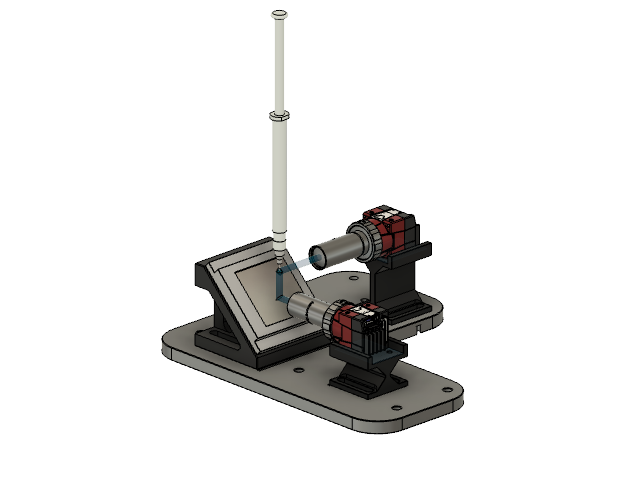

To align multiple needles with micrometer accuracy, we created a custom dual camera optical alignment system. Briefly, two 1×, 40- mm WD CompactTL Telecentric C- mount Lens (Edmund Optics, #63- 745) were mounted to Alvium 1800 U- 500 (Allied Vision) USB cameras. A custom 3D- printed alignment plate and XY positioning system allowed for focus adjustment to achieve parfocality. To image the bottom needle tip to obtain the XY position and needle diameter, a mirror (Thorlabs, ME2S- G01) was mounted at a 45° angle. The second camera was mounted perpendicular to the XY camera to view the side profile of the needle tip for Z- height alignment. A custom LabView program was written to simultaneously view the XY and Z positions.

Additional Open-source Hardware

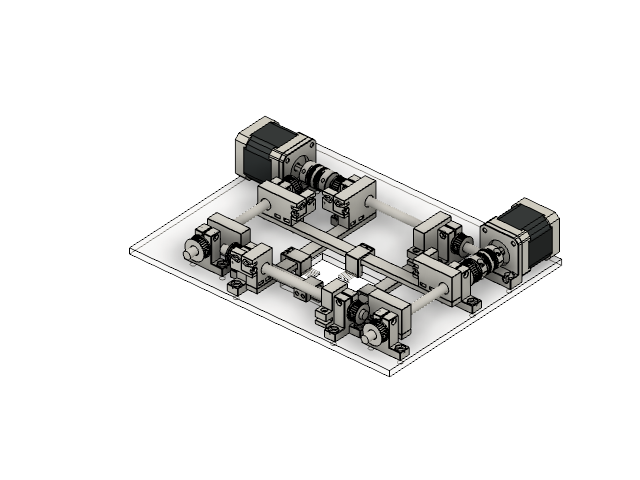

We have developed a 3D printed Open source Biaxial Stretcher (OBS) to be a low-cost stage top mountable biaxial stretching system for use with live cell fluorescence microscopy in both upright and inverted microscope configurations. Our OBS takes advantage of readily available open source desktop 3D printer hardware and software to deliver a fully motorized high precision (10 ± 0.5 µm movement accuracy) low cost biaxial stretching device capable of 4.5 cm of XY travel with a touch screen control panel, and an integrated heated platform with sample bath to maintain cell and tissue viability.